Quality

Product Quality, Right First Time (RFT) and Customer Satisfaction are very important to us and followed in all our activities. Accordingly, special importance is attached to quality control.

Therefore we constantly monitor our operational processes and aim that due to their continuous development these processes can enable us to offer such a service, which, as we do hope, far exceeds customers’ expectations.

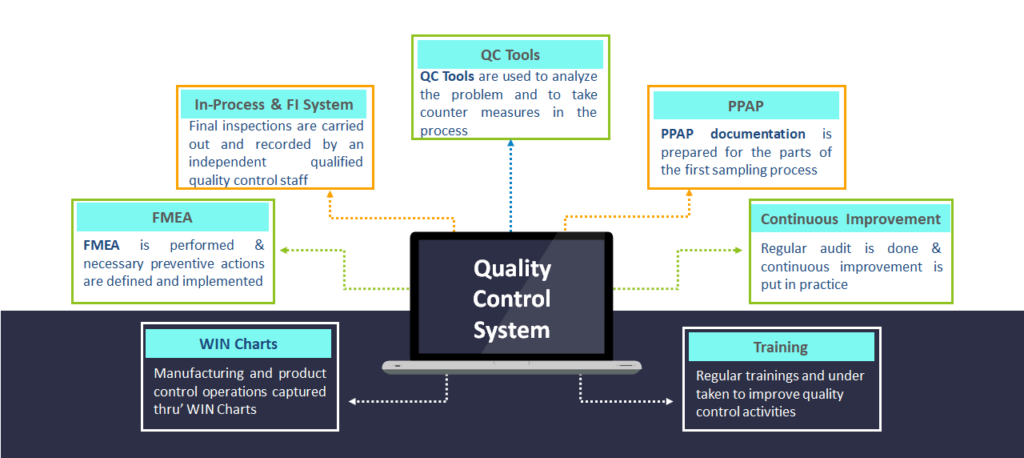

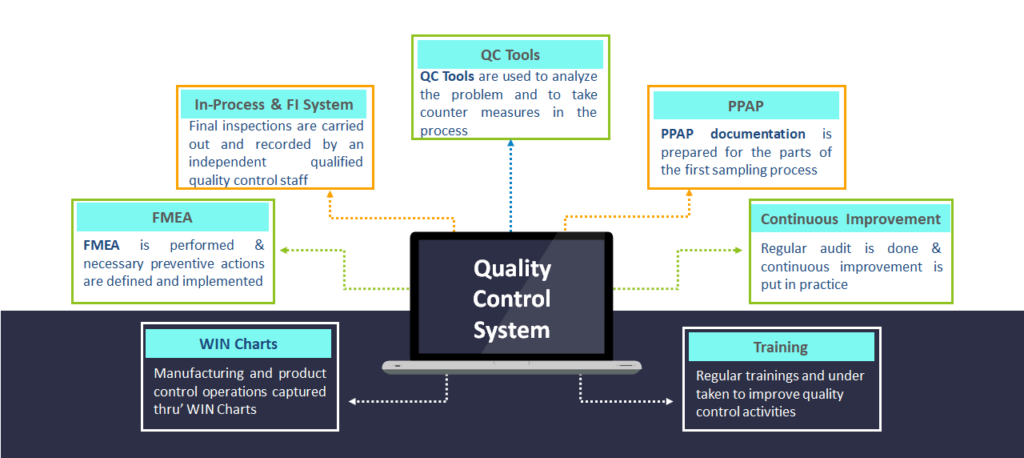

Summary of our quality control activities:

In order to meet the requirements of the high degree of accuracy and the quality expected from our Customers we control our manufacturing processes and the quality of the manufactured sheet metal component. We set up a measuring room equipped with all the necessary tools so we can provide the environment for measuring and testing.

Calibration of measuring instruments are done only by accredited measurement lab.

- Surface Table : 2000 mm x 1000 mm – Grade “0”

- Digital Vernier Calipers

- Digital and analogue protractors

- Digital micrometers

- Height gauges

- Bore and thread gauges

- Fast thickness gauges

Surface Table :

- Size : 2000 mm x 1000 mm

- Accuracy Grade : 0